Home page Products Liquid-Management - by Omnifit/Diba & Bio-Chem ... Piston pumps - Maestro and Maestro ULTRA

Home page Products Liquid-Management - by Omnifit/Diba & Bio-Chem ... Piston pumps - Maestro and Maestro ULTRA

Piston pumps - Maestro and Maestro ULTRA

The challenge faced by the Bio-Chem Fluidics engineers was clear: design and build a piston pump that exceeds the accuracy and life expectancy of competitors' products. And they delivered!

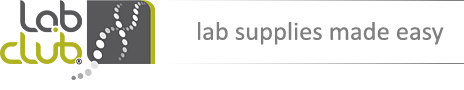

Maestro

Maestro is driven by a 24 VDC Nema stepper motor and is ideal for IVD and similar low-pressure applications. All critical parts are produced by precision machines rather than being moulded. Thanks to the obvious advantages of tolerance control during manufacturing, Maestro offers reliable, consistent and superior performance for even the most demanding applications - and that for more cycles than any application could require.

For additional information, please check out these documents:

Maestro ULTRA

Maestro is widely regarded as the most feature-packed, accurate and durable range of piston dispense pumps for IVD and other low-pressure applications. Based on these successful products, Maestro ULTRA has been developed specifically to resist the impact of agressive solutions such as bleaches, buffers and saline. Using new technolgies and materials, Bio-Chem Fluidics has produced a maintenance-free pump.

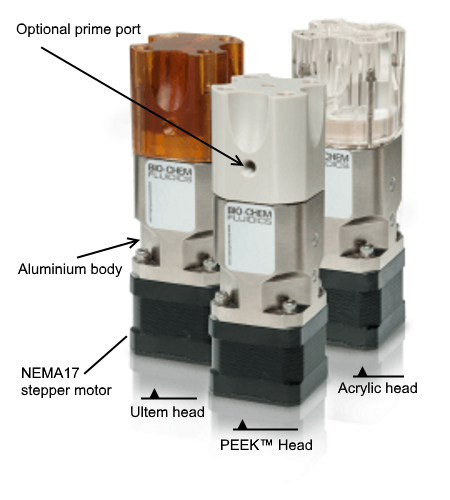

Left: the piston from a standard pump after 1 million cycles with 10% NaOH

Right: a Maestro ULTRA piston after 3 millionen cycles with 10% NaOH !

The "Non-Stick" solution - why ULTRA works

a

NO salt adhesion + NO wear and tear of the seal + NO leaks + NO failures = NO maintenance

In standard pumps, remnants of fluid collect on the piston as it passes through the seal. The moisture eventually evaporates, leaving behind salt crystals adhered to the piston surface. In the course of time this layer thickens and abrades the seal as the piston passes back and forth, causing grooves, leaks and ultimately, pump failure.

The groundbreaking, patent pending Maestro ULTRA technology enables construction of a pump that avoids the seal abrasion otherwise associated with salt solutions.

Super-hydrophobicity

The product development engineers utilize super-hydrophopic materials for Maestro ULTRA. Due to their extremely low wettability, hardly any media can bypass the piston seal, thus minimizing the formation of salt crystals.

Very low surface energy

The extremely low surface energy of the piston prohibits the adhesion of unwanted materials - any salt crystals that do occur simply flake off.

Please check out these documents for additional information:

Basic Specifications:

- Dispense volumes: 50, 100, 250, 500, 1000, 2500 and 5000 µl

- Accuracy: < 0,2% CV

- Complete stroke: 12.7 mm

- Pmax: 500 psi / 3.45 MPa / 34.47 bar

Options:

- Seal flushing port

- Manifold mounting

- Optcal encoder

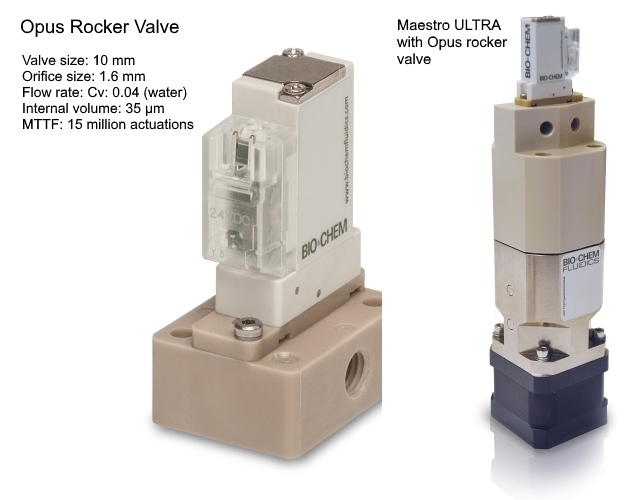

- Integrated 3-way Opus rocker valve - see the photo for additional information

Ordering Information:

Due to the choice of materials, stroke volumes and other options, more than 100.000 configurations are possible! Showing all of them would inevitably cause confusion. Instead, a part number system is used to represent the various possibilities.

If you're interested in Maestro or Maestro ULTRA, please click here to see the ordering information and to determine the part number of "your" pump. Subsequently, please contact us with the part number and quantity - we'll send you the pricing and delivery information. Thank you.